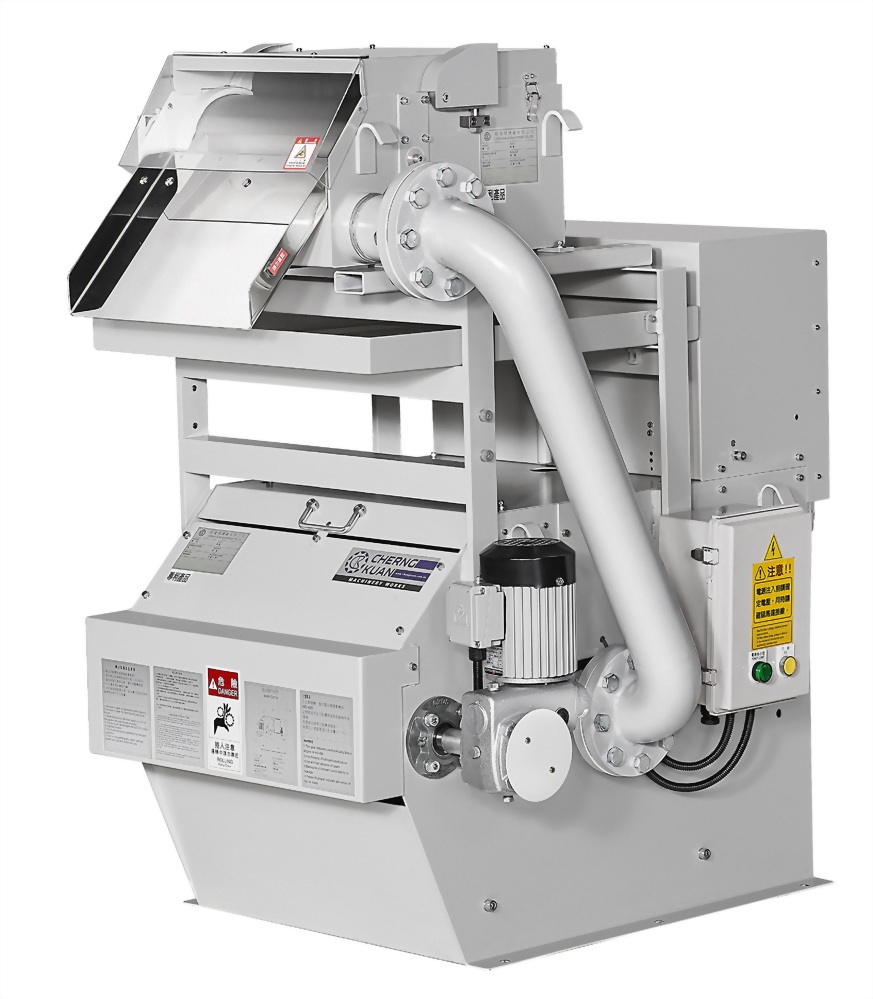

Drum Type Filter

FEATURES

Strain ordinary big and fine grains.

Strain large flow volume of cutting fluid from several machines at the same time.

Straining area and straining volume are big.

Sensor type paper feeding effectively reduces the consumption of filter paper.

The conveying chain and the support nets made of stainless steel have longer service lives.

Straining tolerance varies depending on the thickness of the filter paper which may be 0.25µ, 0.35µ, 0.5µ thick.

Strain ordinary big and fine grains.

Strain large flow volume of cutting fluid from several machines at the same time.

Straining area and straining volume are big.

Sensor type paper feeding effectively reduces the consumption of filter paper.

The conveying chain and the support nets made of stainless steel have longer service lives.

Straining tolerance varies depending on the thickness of the filter paper which may be 0.25µ, 0.35µ, 0.5µ thick.

Model :

B5

Attach:

Taiwan patent no.

M560939/M560940/M560944

FEATURES

- Strain ordinary big and fine grains.

- Strain large flow volume of cutting fluid from several machines at the same time.

- Straining area and straining volume are big.

- Sensor type paper feeding effectively reduces the consumption of filter paper.

- The conveying chain and the support nets made of stainless steel have longer service lives.

- Straining tolerance varies depending on the thickness of the filter paper which may be 0.25µ, 0.35µ, 0.5µ thick.

Major Functions

Strain metal and non-metal chips. The straining result varies dependingon the precision of the filter paper.

Applications

To be used in surface grinding machine, precision grinding machine, polishing machine, horning machine, inner/outer grinding machines, centerless grinding machine, electric discharge machine and laser engraving machine.

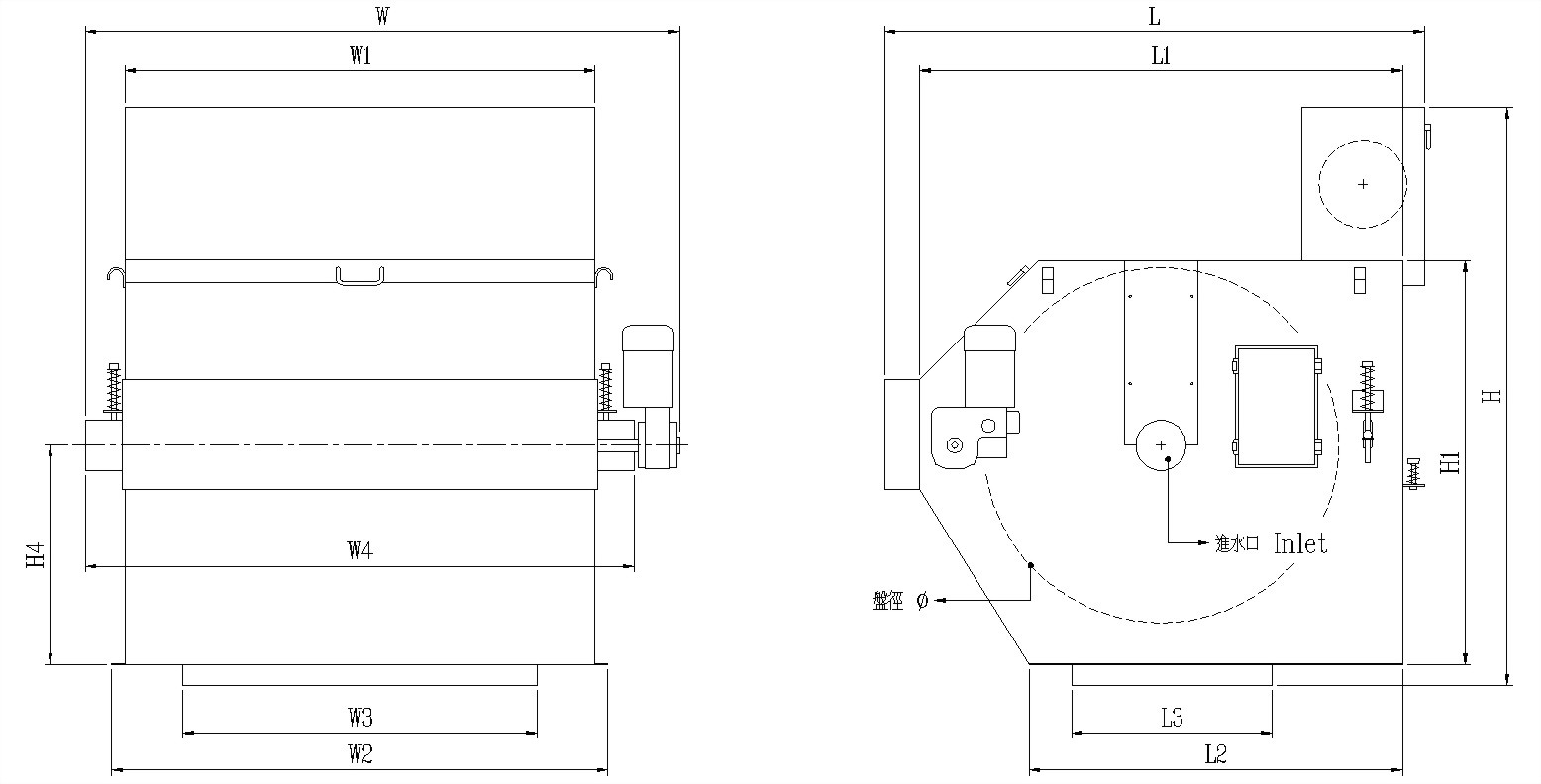

標準尺寸表

| Model | L/Min* | L | W | H | L1 | W1 | H1 | L2 | W2 | L3 | W3 | W4 | H4 | Inlet | (ψ) | (mm) | (HP) | The machine models which are suitable to install this magnet filter | |||||

| B5 | 150~250 | 980 | 830 | 680 | 845 | 570 | 630 | 730 | 650 | 360 | 450 | 750 | 330 | PT-3" | 525 | 500 | 1/4 | LAF24 | |||||

| B57 | 200~350 | 980 | 1030 | 680 | 845 | 770 | 630 | 730 | 850 | 360 | 650 | 950 | 330 | PT-3" | 525 | 700 | 1/4 | LAF30、XAF24 | |||||

| B7 | 250~450 | 1150 | 1030 | 900 | 1020 | 770 | 850 | 870 | 830 | 450 | 600 | 950 | 450 | PT-4" | 725 | 700 | 1/4 | LAF36、XAF30 | |||||

| B710 | 350~550 | 1150 | 1330 | 900 | 1020 | 1070 | 850 | 870 | 1130 | 450 | 800 | 1250 | 450 | PT-4" | 725 | 1000 | 1/4 | XAF36 | |||||

| B10 | 500~800 | 1230 | 1330 | 970 | 1100 | 1070 | 920 | 850 | 1130 | 450 | 800 | 1250 | 500 | PT-4" | 825 | 1000 | 1/4 | - | |||||

| B15 | 700~1000 | 1230 | 1730 | 970 | 1100 | 1470 | 920 | 850 | 1530 | 450 | 1350 | 1650 | 500 | PT-4" | 825 | 1400 | 1/2 | - | |||||

*The amount of processed water is the result of the test of clean water.

※The specifications are subject to change without notice in advance.

※Special specifications can be customized.