Magnet Filter

FEATURES

Strain metal chips in coolant fluid. No filter paper is required.

The chip outlet has no magnetism so that chip removing is smooth.

Suck and remove the carbon peeled layers from super hard alloy and quenched steel

Oil soluble grinding liquid can be perfectly strained. Thus, the 2ndstraining work becomes easier.

Strain metal chips in coolant fluid. No filter paper is required.

The chip outlet has no magnetism so that chip removing is smooth.

Suck and remove the carbon peeled layers from super hard alloy and quenched steel

Oil soluble grinding liquid can be perfectly strained. Thus, the 2ndstraining work becomes easier.

Model :

S8

Attach:

Taiwan patent no.

M251648/M314072/M295548

FEATURES

- Strain metal chips in coolant fluid. No filter paper is required.

- The chip outlet has no magnetism so that chip removing is smooth.

- Suck and remove the carbon peeled layers from super hard alloy and quenched steel

- Oil soluble grinding liquid can be perfectly strained. Thus, the 2ndstraining work becomes easier.

APPLICATION

Surface grinder, fine-grinding machine, polishing machine, honing machine, inner/outer center grinding machine, centerless grinder and electric discharge machine.

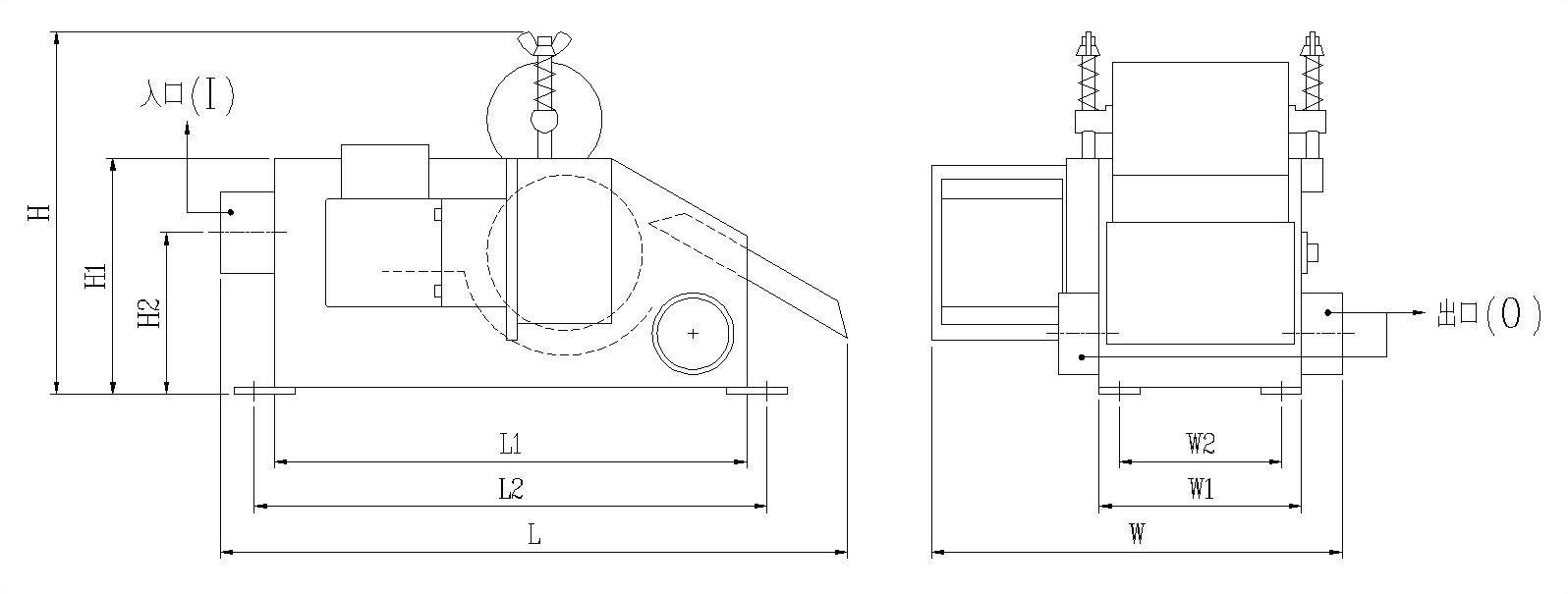

標準尺寸表

| Model | L/Min* | L | W | H | L1 | W1 | H1 | L2 | W2 | H2 | Inlet | Outlet | Motor |

| S4 | 40 | 470 | 310 | 270 | 350 | 150 | 175 | 380 | 120 | 120 | PT-2" | PT-2" | 25W |

| S6 | 60 | 470 | 360 | 270 | 350 | 200 | 175 | 380 | 170 | 120 | PT-2" | PT-2" | 25W |

| S8 | 80 | 470 | 410 | 270 | 350 | 250 | 175 | 380 | 220 | 120 | PT-2" | PT-2" | 25W |

| S12 | 120 | 470 | 460 | 270 | 350 | 300 | 175 | 380 | 270 | 120 | PT-2" | PT-2" | 25W |

| S16 | 160 | 520 | 510 | 310 | 400 | 350 | 210 | 430 | 320 | 155 | PT-3" | PT-3" | 40W |

| S24 | 240 | 570 | 560 | 310 | 450 | 400 | 210 | 480 | 370 | 155 | PT-3" | PT-3" | 40W |

| S30 | 300 | 620 | 660 | 310 | 500 | 500 | 210 | 530 | 470 | 155 | PT-3" | PT-3" | 90W |

| S36 | 400 | 720 | 760 | 310 | 600 | 600 | 210 | 630 | 570 | 155 | PT-3" | PT-3" | 90W |

| Model | L/Min* | L | W | H | L1 | W1 | H1 | L2 | W2 | H2 | Inlet | Outlet | Motor |

| L6 | 80 | 470 | 355 | 330 | 350 | 200 | 235 | 380 | 170 | 175 | PT-2" | PT-2" | 25W |

| L8 | 100 | 470 | 405 | 330 | 350 | 250 | 235 | 380 | 220 | 175 | PT-2" | PT-2" | 25W |

| L12 | 130 | 564 | 460 | 330 | 450 | 300 | 235 | 480 | 270 | 175 | PT-3" | PT-3" | 90W |

| L16 | 180 | 546 | 510 | 330 | 450 | 350 | 235 | 480 | 320 | 175 | PT-3" | PT-3" | 90W |

| L24 | 280 | 546 | 560 | 330 | 450 | 400 | 235 | 480 | 370 | 175 | PT-3" | PT-3" | 90W |

| L30 | 350 | 574 | 665 | 330 | 500 | 500 | 235 | 530 | 470 | 145 | PT-4" | PT-4" | 90W |

| L36 | 450 | 735 | 765 | 330 | 600 | 600 | 235 | 630 | 570 | 145 | PT-4" | PT-4" | 90W |

| Model | L/Min* | L | W | H | L1 | W1 | H1 | L2 | W2 | H2 | Inlet | Outlet | Motor |

| X8 | 120 | 660 | 420 | 360 | 500 | 250 | 260 | 530 | 220 | 175 | PT-3" | PT-3" | 90W |

| X12 | 170 | 660 | 470 | 360 | 500 | 300 | 260 | 530 | 270 | 175 | PT-3" | PT-3" | 90W |

| X16 | 220 | 660 | 520 | 360 | 500 | 350 | 260 | 530 | 320 | 175 | PT-3" | PT-3" | 90W |

| X24 | 300 | 670 | 570 | 380 | 550 | 400 | 280 | 580 | 370 | 170 | PT-4" | PT-4" | 90W |

| X30 | 400 | 720 | 670 | 380 | 600 | 500 | 280 | 630 | 470 | 170 | PT-4" | PT-4" | 90W |

| X36 | 550 | 820 | 770 | 380 | 700 | 600 | 280 | 730 | 570 | 170 | PT-4" | PT-4" | 90W |

| Model | L/Min* | L | W | H | L1 | W1 | H1 | L2 | W2 | H2 | Inlet | Outlet | Motor |

| XL8 | 700 | 790 | 1000 | 530 | 630 | 800 | 260 | 680 | 750 | 190 | PT-4" | PT-4" | 1/4HP |

| XL12 | 800 | 850 | 1400 | 610 | 680 | 1200 | 310 | 730 | 1150 | 230 | PT-5" | PT-5" | 1/2HP |

| XL15 | 1000 | 920 | 1700 | 700 | 750 | 1500 | 355 | 800 | 1450 | 260 | PT-6" | PT-6" | 1HP |

| XL18 | 1250 | 920 | 2000 | 700 | 750 | 1800 | 355 | 800 | 1750 | 260 | PT-6" | PT-6" | 1HP |

*The amount of processed water is the result of the test of clean water.

※The specifications are subject to change without notice in advance.

※Special specifications can be customized.